Orthopedic Power Equipment

Whittemore Brand Orthopedic Power

Orthopedic Power

Orthopedic Accessories

Arthroscopy

Orthopedic Implants

Orthopedic Equipment

ORTHOPEDIC POWER EQUIPMENT

Small bone power equipment

Small bone power equipment is designed to meet the needs of the surgeon working on extremities and the smaller bones of the body. Specialties that use this kind of equipment include podiatry/foot and ankle surgery, hand surgery, oral and maxillofacial surgery, and small animal veterinary surgery.

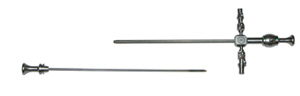

There are a wide variety of hand pieces in this category. Systems are often modular, with a single driver and various attachments. Each attachment has a specific purpose: wire drivers, Steinman pin drivers, Jacobs chucks, available in 1/4” or 5/32”, keyless chucks, AO/Synthes, Trinkle, and Hudson quick release attachments.

Drills and drivers are used with various attachments, such as Jacobs chucks, keyless chucks, pin drivers, wire drivers, and quick release attachments.

Wire drivers are used for running K-wires.

Burr drivers run at different speeds for bone shaping, cutting and drilling. There are a variety of burr guards (used to stabilize the burr) and angled burr attachments for different positions and burr types.

Saws are designed for a specific type cut, with specific blades for each.

- Sagittal saws cut in an up and down or side to side motion along the horizontal axis of the hand piece.

- Reciprocating saws cut in a back and forth motion along the horizontal axis of the hand piece.

- Oscillating saws cut with an oscillating motion. The blades attach at a 90 degree angle to the distal end of the hand piece.

Large bone power equipment

Large bone power equipment is designed for large bone procedures like hip replacement, total knee replacement, reaming, intramedullary nailing, drilling and driving screws. Ideal for the surgeon that prefers a maximum power system rather than the more delicate small bone drills and saws, this type of equipment is often used by trauma surgeons or in large animal veterinary surgery.

As with small bone systems, large bone power systems are often modular. The saws are usually individual, dedicated hand pieces, with drills and drivers having attachments (such as Steinman pin drivers, Jacobs chucks, available in 1/4” or 5/32”, keyless chucks, AO/Synthes, Trinkle, and High Torque quick release attachments, Hudson and Synthes reamers) to perform particular functions.

The sagittal saw is sometimes called an oscillating saw, however in large bone handpieces they are the same thing. There is the reciprocating saw and the sternum saw, which has a special guards to protect vital organs while cutting through the sternum.

We offer orthopedic power equipment in pneumatic, electric and battery operated configurations, and there are advantages and disadvantages to each.

Battery driven devices:

Advantages:

-

Portability, excellent for ambulatory practices.

-

No hoses or connection cables to deal with.

-

Very good for maintaining a sterile field.

-

Available in small bone systems.

-

Hospital-preferred for large bone systems for knees and hips.

Disadvantages:

- Sterilization in a table top autoclave is time consuming and will shorten battery life. (Table top autoclaves take 15 to 20 minutes to reach temperature, then 20 minutes at 250' to achieve sterilization.)

- The recommended sterilization procedure for batteries is flash sterilization. (This requires a sterilizer with flash capabilities. A free-standing system with steam generator produces steam at 270' and forces it into the chamber for 3 to 10 minutes, achieving sterilization without cooking the contents. Gas sterilization is a good alternative if you have an ethylene oxide system.)

- The drop-in battery system solves the problem of sterilizing batteries. It incorporates a battery holding module that is autoclavable, and a drop-in battery that is not autoclaved. There is a shield to prevent the non-sterile battery from touching the sterile holding module while the battery is being dropped in. This option is not available for every brand or model.

Electric systems:

These are primarily small bone devices, powered by electric motors and circuit boards in the sealed hand piece. Hand pices are powered by a console via a cable connection.

Advantages:

-

Portability, excellent for ambulatory practices.

-

Multiple hand piece options are all run by the same console. Some even have arthroscopy shavers.

-

Very good for maintaining a sterile field.

Disadvantages:

-

Sterilization is hard on electric components and circuit boards. Gas sterilization is a good alternative if you have an ethylene oxide system.

Pneumatic driven devices:

It is recommended that these be powered by nitrogen, as it is clean, dry, and free of contaminants. Nitrogen can be acquired from any medical gas provider worldwide.

Advantages:

-

Longer life expectancy. Hand pieces and air hoses last longer when autoclaved in table top sterilizers.

-

Power is better in most products, specifically the high-speed hand pieces.

Disadvantages:

-

Nitrogen tanks take up room and have to be regularly monitored and refilled. For an ambulatory practice it is not practical or advisable to move tanks around.

-

Air hoses are cumbersome and limit accessibility.

Service and maintenance

Regular service is necessary for all power hand pieces.

Pneumatic hand pieces generally hold up longer than devices with an electric motor, but over time they will gradually lose power and torque as the turbine wears. You may not notice the power loss.

Failures

The most common cause of hand piece failure is lack of necessary regular maintenance. Without regular service, the device will run with less power, will stop intermittently or stop running altogether. This is caused by the internal buildup of dirt and corrosion, as well as wear from regular use and the sterilization process.

Hand pieces that are run while still hot or warm from autoclaving can bind up and stop running. This is caused by heat expansion of metal and other materials within the motor. Moisture can cause the same problem, which is why proper drying is very important.

Battery operated hand pieces should be positioned in an appropriate sterilization case so they can dry properly after sterilization.

Warning

Compressed air

The use of compressed air to run pneumatic hand pieces is not recommended. Although it will run pneumatic hand pieces, compressing room air creates moisture. Not only will this moisture cause the hand piece to freeze up and stop running, it also causes rust, mold, and bacteria growth in the holding tank. This creates contaminated particulate that is dispersed right into the sterile field. While a filter and a dryer can be added to the compressor, there is still the issue of bacteria and mold spores contaminating the sterile field.

Warning

Non-medical and/or un-sealed devices

Some battery driven or electric motor drills and saws, such as Black & Decker drills and Stryker cast saws (or other brands), are often used for orthopedic surgery, with the addition of a sterile shroud.

Caution – Such drills incorporate an armature with carbon brushes.

You may have noticed sparks inside these devices. These sparks are caused by the brushes wearing on the armature. This, along with the fan effect, is essentiality blowing microscopic contaminate into the sterile field.